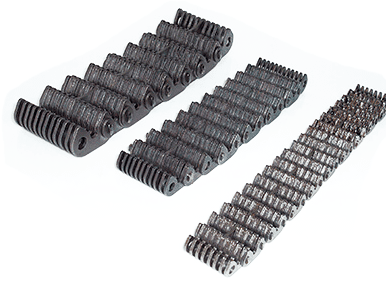

HC High Performance Inverted Tooth Chain

HC High Performance Inverted Tooth Chain

For High Velocity, High Horsepower and High Efficiency Drives with smooth transmission of load in a compact space.

‘HC’ Inverted Tooth Chain Drives

You get more with ‘HC’

The features of ‘HC’ link design, compensating pin and rocker joint, with the involute hobbed sprockets means HC chain can transmit more power, at higher speeds, in less space than other transmission media, with smooth action and minimum of noise.

High Speed Performance Operating chain speeds range from 10 to 35 metres per sec. with higher speeds (to 55m/sec) on special applications.

High Power in Narrow Widths HC chain transmits more power per inch of width than any other chain or belt drive, with capacities up to 6000 kW.

Smooth Quiet Operation The rolling action of the chain joints combined with smooth sprocket engagement minimise induced vibrations. This enables HC chain to provide quiet drives on high speed applications.

High Efficiency Smooth operation, with minimal frictional losses, provide transmission efficiencies up to 99.7%.

‘HC’ Chain - Selection

There are Seven good reasons to use HC in your design! HC transfer cases provide weight and cost savings because:

- Fewer Shaft and Bearings are required.

- Lighter Loads on Shaft Bearings.

- Chain Bearing Loads are compressive, placing case in compression, unlike gear forces which are tensile.

- HC Cases are Lighter as compressive loads mean thinner sections can be used.

- Centre Distance is less Critical and more flexible than required by gear and belt drives.

- Elasticity of HC Chain accommodates normal thermal expansion, and helps ‘cushion’ the drive.

- Simplified Design results in a positive cost saving.