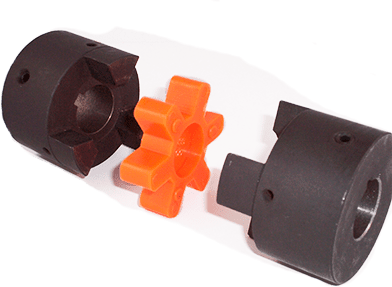

'L' Series Couplings Elastomeric Jaw Couplings

‘L’ Series Jaw Couplings

Simple, economical design and fully interchangeable with industry standards.

'L' Series Couplings Elastomeric Jaw Couplings

Cross+Morse has expanded its comprehensive family of quality industrial couplings to include the Type ‘C’ Jaw, offering a uniquely simple design combined with misalignment capability and maximum economy. The ‘L’ coupling contains only three components: two jaws and one ‘spider’ insert. Power is transmitted between the jaw halves by the insert, which is offered in a choice of four materials to suit all the application characteristics and horsepower requirements. All sizes are dimensionally interchangeable with industry standards, making replacement in existing installations easy and economical. Type ‘L’ Jaw Couplings are designed for light to medium duty applications up to 112 Kw at 1500 rpm, and are available for shaft sizes from 1/8” (3.2mm) to 60mm.

‘L’ Series Couplings offer a choice of 4 insert types for maximum versatility

Type ‘L’ Jaw Couplings are designed for applications in the light-to-medium duty range, with capacities and performance characteristics depending on the type of insert used. For maximum versatility in selection, Cross+Morse offers four different insert materials to suit the application.

Buna-N: This is the standard flexible insert material in Type ‘L’ Jaw Couplings, serving the majority of applications. The materials is an oil resistant rubber compound with excellent flexibility and shock absorption; temperature range is –40°C to +100°C.

Urethane: The urethane insert offers approximately 50% greater torque capacity than standard Buna-N, and in addition provides good chemical resistance. Temperature is –35°C to 70°C.

Hytrel®: This tough flexible plastic material provides still greater torque capacity, approximately three times that of standard Buna-N, and superior temperature resistance with a range of –50°C to +120°C. Oil and chemical resistance are excellent.

Bronze: This insert is intended exclusively for high torque, low speed applications, up to 250 rpm only. Capacities are three times those of standard Buna-N. The material offers excellent resistance to oils, chemicals and extreme temperatures –40°C to +230°C.